Downsizing and enterprise stacking makes Kent farm financially resilient

If ideas and enterprise stacking rather than scale and focus make a farming business resilient, then Doug Wanstall is onto a winner.

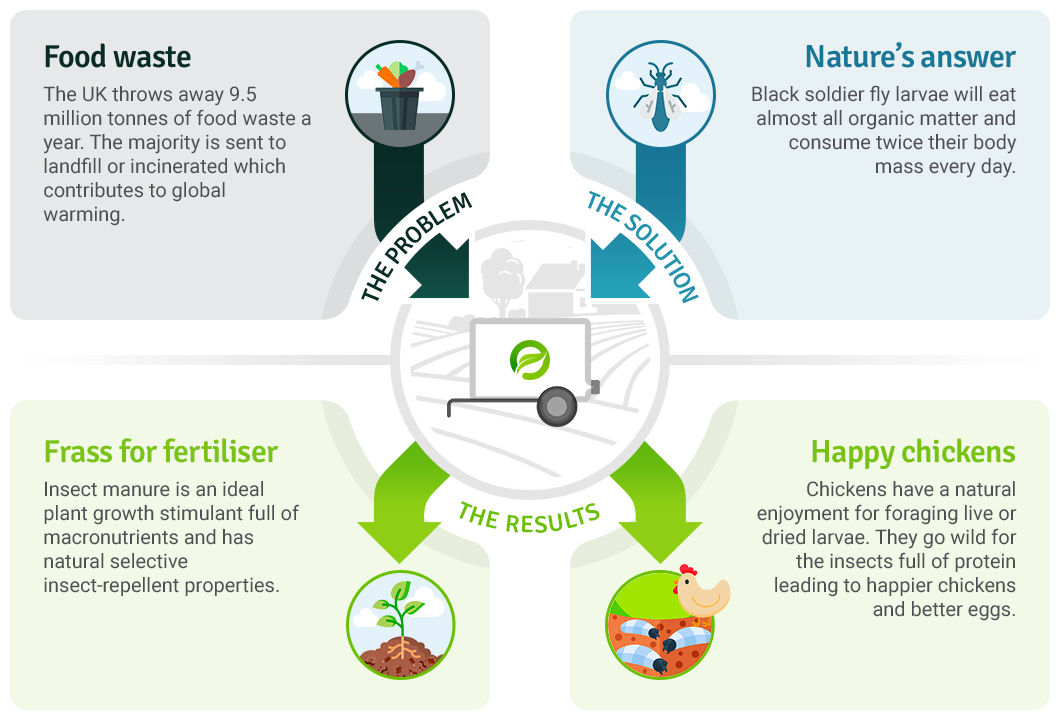

Black Soldier Fly Larvae can naturally convert food waste into animal feed and fertilise